How to Decarbonize Your Supply Chain: Ørsted’s Path to Net-Zero Carbon Emissions

How to Decarbonize Your Supply Chain

Ida Krabek and Virginie Van de Cotte share insights on Ørsted’s path to net-zero carbon emissions.

Introduction

Expectations for companies to act on climate change are high and growing. In response, many organizations have stepped up and committed to achieving net-zero emissions across their operations and often large, complex supply chains. Moving from ambition to action and building a clear, credible roadmap remains a challenging task.

Ørsted, an energy company based in Denmark, has been an innovative leader in this area. Over the last decade, it has transformed from one of the most coal-intensive energy companies in Europe to a global green energy leader. In 2021, Ørsted became the first energy company to have its target to achieve net zero across its entire value chain by 2040 approved by SBTi as science-based.

Ørsted’s Senior Director and Head of Global Sustainability, Ida Krabek, and Chief Procurement Officer, Virginie Van de Cotte, share insights on the journey so far, the challenges Ørsted has faced, and their advice to others on how to decarbonize their supply chains.

Key lessons to take away

Develop a clear, long-term, and holistic vision that is embedded in strategy, culture, and decision-making.

Build a collaborative partnership between procurement and sustainability leaders and teams and work closely together.

Use a science-based approach and external standards to build credibility, provide a common, shared language for stakeholders, and develop a clear roadmap for action.

Partner with strategic suppliers on their decarbonization journeys to build a shared understanding of the business case and issues, build capacity and define the required steps.

Focus on the parts of your supply chain that are most difficult to decarbonize and team up to overcome systemic barriers and create market demand for nascent technologies.

Partner with other companies across the industry and beyond to advocate for change and create enabling conditions for suppliers.

What has Ørsted achieved so far?

Today, more than 85% of the energy Ørsted provides comes from renewable sources, including offshore wind and bioenergy.

On track to become carbon neutral in its operations and energy generation (Scopes 1 and 2) by 2025. That will see its carbon intensity fall by at least 98% compared to 2006.

The company expects all of its Tier 1 suppliers to cover their electricity consumption with 100% renewable electricity by 2025.

“Sustainability is so important to our strategy. It’s not about reporting it, it’s about living it. The next frontier is our supply chain. We strongly believe we have a voice and role to play in our industry to create awareness and be a catalyst for sustainable action. We must work with our suppliers to do this. We depend on them to achieve our sustainability goals.”

- Ida Krabek

Key challenges and success factors for Ørsted’s Net Zero program

1. Develop a clear, long-term vision that’s embedded in the business

In 2009, Ørsted’s management announced a major strategic shift: to reverse the 85/15 mix of revenues from fossil fuels to renewables by 2040 – a goal it met in 2019. It’s been a rewarding but also challenging journey. The business faced internal skepticism, steep learning curves, and the need to remain economically competitive throughout the transformation.

A key factor in Ørsted's success has been leadership’s strong vision and emphasis on recognizing the need to balance short- and long-term business risks and opportunities. "There's been many difficult choices and risk assessments to do along the way. Throughout the transformation, our leadership has maintained its firm belief that the future of energy is renewable and not fossil energy. There was also a huge business opportunity in getting it done rather than wait,” says Ida.

Deeply integrating this vision into Ørsted's strategy and culture has taken hard work and extensive collaboration. "One of the key parts is to ensure that you bring sustainability not only into your corporate strategy but also the strategies of your business functions,” says Virginie. Ørsted have backed this up by making decarbonization integral to leadership’s short-term incentives and business KPIs.

2. Build a roadmap with science-based targets and reporting

One of the biggest challenges facing companies is mapping out the near-term and long-term reductions needed and creating a concrete, actionable roadmap for how to get there.

For Ørsted, utilizing the Science Based Targets Initiative (SBTI) approach and shared CDP reporting framework have been pivotal to charting the course and accelerating progress. For a company to have an SBTI-validated target, net-zero must be achieved primarily through emission reductions (not offsetting) and address significant contributors across the value chain, including Scope 3 emissions.

"We set our first science-based target in 2016 and just going through that process was a big learning experience for us. Together with our CDP reporting, it has been extremely important in shaping our climate action plan and our ambitions,” says Ida. "Creating a baseline and understanding the biggest challenges is the first step. That understanding makes it easier to drive decision-making and figure out the meaningful actions to take." The verification of the plan by SBTI also gives the company credibility when seeking to work with and influence suppliers and other stakeholders.

“Seek out verification from trusted third parties. Science-based targets and doing CDP reporting are key parts of the solution for us. They have been instrumental in informing our roadmap and ensuring we all speak the same language, which is one of the most important parts of moving the supply chain decarbonization agenda forward. We also use that credibility to show our partners and customers that we can help them realize their sustainability ambitions.”

- Ida Krabek

3. Forge a strong partnership between sustainability and procurement leaders and teams

The Ørsted sustainability and procurement teams must work closely together to implement the roadmap and achieve their goal for a net-zero supply chain. There have been challenges along the way where the priorities and goals of the two functions pull in different directions. But Ida and Virginie have shown how these can be overcome and even leveraged for good through an open, collaborative approach.

3.1 Embrace a healthy tension between Sustainability and Procurement

"I think it's a healthy challenge. The sustainability team needs to drive as much change as possible. And then you have procurement considering the commercial part. So it's that balance of those two different elements. As leaders you need to show that you are aligned on the direction and then the organization can come closer together,” says Virginie.

In practice, this partnership means that Ida’s team helps keep Virginie and her team well-informed about regulatory developments, sustainability standards and other factors shaping the landscape around sustainable supply chains and net zero. Virginie brings Ida and her team into the process of shaping the procurement strategy, while she supports them in reporting to management, and the teams work collaboratively on day-to-day priorities and actions.

3.2 Clearly identify roles and responsibilities for each function

Virginie and Ida advise companies to clearly identify distinct roles for each function. Both agree that the procurement team should lead on engaging and working directly with suppliers since it owns these relationships. The sustainability function provides guidance on what leadership looks like, the direction and goals, and how to get there. "Be good at sharing what's going on out there - the regulatory developments, what competitors are doing, what leaders are doing in the space, and what expectations we’re seeing from our customers,” says Ida.

“It’s extremely important that the solutions are driven by and through the procurement organization, so that it becomes a part of our day-to-day work and priorities.”

- Virginie Van de Cotte

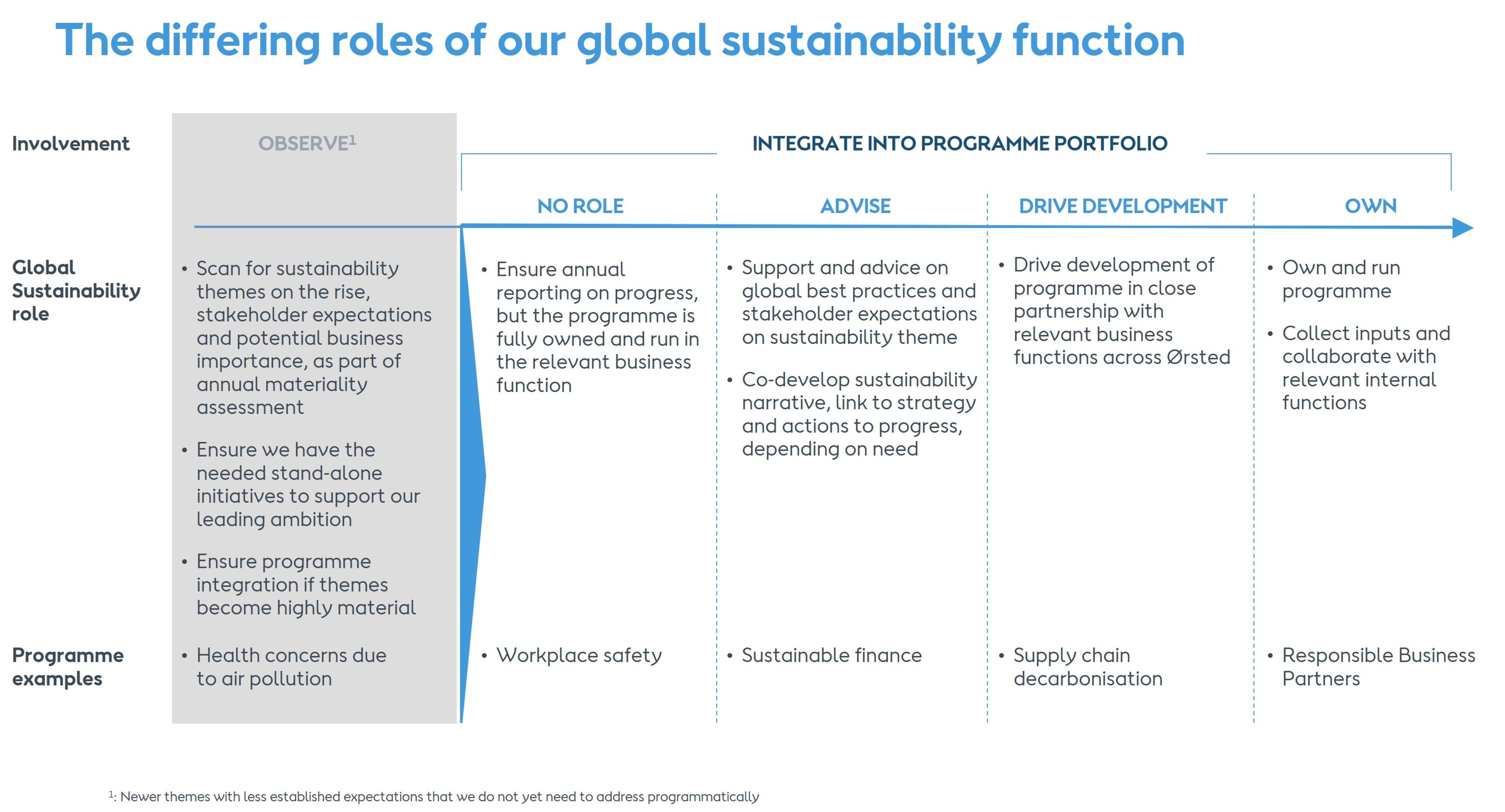

3.3. Equip the Sustainability team to support the business

Ørsted’s Sustainability team has identified four types of involvement that it can have to support the business: 1) No role; 2) Advice; 3) Drive development; and 4) Own. Supply chain decarbonisation falls into the Drive Development category. In this case, the team partners closely with Procurement and other functions to help develop and drive the approach and develop solutions. "A big part of what we do in global sustainability is to get the right people around the table because a lot of these sustainability topics have to be solved in collaboration between business functions who don’t necessarily work closely together and their differing perspectives are needed to find ways forward,” explains Ida. The chart below identifies the four types of roles and related examples.

Offering a complementary mix of skills and capabilities is also a key part of the sustainability team’s DNA and success. Change management is an especially important area for engaging business partners and embedding sustainability in the business. "The global team includes a mix of deep topic matter experts within both the environmental and social space and people who have very strong backgrounds in driving change and programs in big corporations or consultancy,” explains Ida.

4. Understand your supply chain and identify where to prioritize

Like other companies, Ørsted’s supply chain is complex and far-reaching, covering hundreds of suppliers across multiple sectors around the world. The scale is daunting, and it can be hard to know where to start and how to have the most impact. So, identifying where to focus attention and resources is key.

The first step for Ørsted was to focus on the suppliers where it has the most influence and impacts are greatest. "A meaningful play for us was to start by working with our strategic suppliers who account for the majority (=>60%) of our total procurement spend and start the conversation with them,” says Virginie.

As the program progresses, it is moving to work with the full supply base including indirect suppliers, suppliers that are less mature in their net zero journey, and those in regions with less enabling factors (e.g., access to renewable energy).

5. Identify how your business can support suppliers to make the transition

Companies like Ørsted must work with suppliers with various levels of awareness and maturity on sustainability and net zero. Decarbonizing can initially lead to higher costs for suppliers, which then presents potential risks for market competitiveness. So how can suppliers be encouraged to take action?

Virginie and Ida believe a collaborative approach is vital and businesses should identify the tools and levers their company can use to support suppliers. "We don’t want to be there only to demand, but really to work together to be successful,” explains Virginie.

5.1 Help suppliers understand and make the business case for decarbonizing

Ørsted began by helping suppliers understand the business case for decarbonization and the risks of inaction. Ørsted has created materials and guidance to support the dialogue, including on the local regulatory and governance landscape where they operate. "Every government in Europe and the US is promising high targets for the use of renewable energy. Our supply base must be ready,” says Ida. Ørsted are also advocating for low-cost loans to help suppliers make the investments to decarbonize.

“Share knowledge, communicate the business case and explain the ‘why’ behind decarbonization. We explain to suppliers what’s happening out there – investor expectations, upcoming regulations, civil society and NGO agendas, and customer expectations – and help to paint a picture of the need to take action and the likely impact on businesses if we don’t.”

- Virginie Van de Cotte

5.2 Support suppliers with building their roadmaps and embedding sustainability

Ørsted opened the conversation with their strategic suppliers by encouraging them to start reporting to CDP and to set science-based targets. The next step was supporting suppliers to create a roadmap and identify opportunities for action – even if small steps in the short term. Visibility and consistent communications are also important.

Virginie makes sure that sustainability is part of the agenda for every supplier meeting. "It creates awareness. You need to encourage your suppliers to bring sustainability into the DNA of each of their employees,” she says.

6. Help overcome barriers and drive action in hard-to-transition sectors

It is also vital to identify and take action to support hard-to-transition sectors that would hold up progress on the decarbonization journey. Ørsted identified these as Offshore Logistics and Steel. In these areas, the business faced a difficult process of assessing what is possible in the near term, what it can commit to, and how it can encourage suppliers to act despite the potential financial risks.

Steel accounts for 50% of the emissions of an offshore wind farm. "We need green steel to get to net zero but it’s not available at scale or a commercially viable price if we try and use it for all our projects,” says Virginie.

"As a developer, we do not produce but instead buy most of our products and raw materials. As mentioned, we have target setting with our Tier 1 suppliers, but we also collaborate with Tier 2 suppliers to accelerate their sustainability commitments by advising and supporting them and by collaborating in finding innovative ways to reduce material,” explains Virginie.

Switching to using renewable energy is another key challenge for the steel and shipping industries. Ørsted is supporting these sectors by scaling their production of renewable energy and sustainable e-fuels. In December, Ørsted took full ownership and the final investment decision on FlagshipONE, the largest green e-methanol project in Europe. FlagshipONE will be Ørsted’s first commercial-scale Power-to-X facility and the first e-methanol project in Ørsted’s green fuels pipeline. E-methanol can be used to replace fossil fuels in the shipping industry, which today accounts for around 3 percent of global carbon emissions. Ørsted is also developing the 300,000 ton ‘Project Star’ in the US Gulf Coast area and the ‘Green Fuels for Denmark’ project in Copenhagen, which will both produce significant volumes of e-methanol to enable the decarbonization of shipping.

Ørsted is actively working with suppliers to facilitate the shift toward green energy - drawing on its expertise and opportunities for commercial synergy. For example, in the Offshore Logistics sector, Ørsted recently signed an agreement for the world’s first green fuel service operation vehicle for the world’s largest wind farm, Hornsea 2. The vessels run on renewable e-methanol, produced from wind energy and biogenic carbon.

7. Prioritize strategic collaboration and advocacy to create the right incentives and conditions

Broader partnerships and advocacy are also vital for creating the enabling conditions for suppliers to invest in decarbonization efforts. "The partnerships piece is extremely important. Thinking about who can you partner up with – whether they are in corporate partnerships or across industries like steel – based on who have similar interests and want to be part of pushing for a solution,” says Ida.

7.1 Build a coalition to develop and create demand for nascent technologies

This is a key part of Ørsted’s approach to transforming the steel sector. Together with the Climate Group, they have co-founded SteelZero, a group of companies that have jointly made a public commitment to buy 100% net zero steel by 2050. By harnessing their collective purchasing power and influence, the group is sending a strong demand signal to shift global markets and policies towards the responsible production and sourcing of steel. Ørsted is also a founding member of First Movers Coalition, a coalition of companies using their purchasing power to try to decarbonize seven hard-to-abate industrial sectors, including steel and concrete.

"We are combining forces to deliver a message to steel suppliers that we’re going to demand green steel. This creates awareness and adds additional pressure for suppliers to act, not just from companies like Ørsted but from across other industries too.” says Virginie.

7.2 Advocate for government support and policy

Another focus of advocacy is on increasing government and regulatory support, including the key role of demand from government tenders. To create the right market signals, decarbonization must be part of the requirements in the tender. "We need governments to help create the right incentives and stimulate demand. This is a key area and in our own interest as well as our suppliers, so that decarbonized solutions can become the market standard.” says Ida.

Some final advice

“Acknowledge that this is challenging and it's challenging for everyone. It's challenging for your partners in the organization, it's challenging for us, it's challenging for your suppliers as well. So that's why we've chosen to take this very collaborative approach and to create these ripple effects. What is helpful in the whole sustainability space is that we collaborate, that we share, that we inspire, that we set expectations and we follow up.” - Ida Krabek